Accurate measurements are the key to perfecting anything for professionals. Builders and woodworkers make sure that every piece of their project is measured to preciseness. The same goes for when they operate a table saw.

A calculator becomes mandatory when someone is calculating the angles and lengths of their materials. For instance, finding miter angles is important when joining corners.

To better understand why calculators are important, you need to understand the procedure to precisely measure the materials. But first, let’s clear the basics.

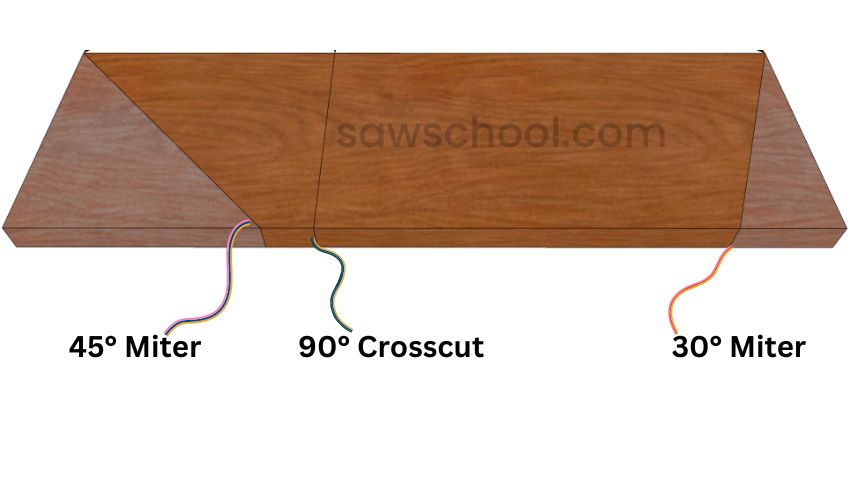

What Is A Miter Cut?

When you cut the material at different or similar angles to create a perfect joint, it’s called a miter cut. Calculating miter cuts is not a difficult procedure to go through. The formula is pretty straightforward.

The angle you want as a whole needs to be divided by two. For instance, let’s consider a picture frame. The corners of a picture frame are a result of two pieces of wood joined together to form a 90-degree angle.

If you divide 90 degrees by 2, you will get 45 degrees. So, you have to cut two pieces of wood at 45 degrees angle and then join them together to complete the 90-degree corner.

This formula will remain the same for similar-sized wood pieces, regardless of what angle you are working with. For instance, even if you are not creating a 90-degree angle, you will still have to divide the whole number by two.

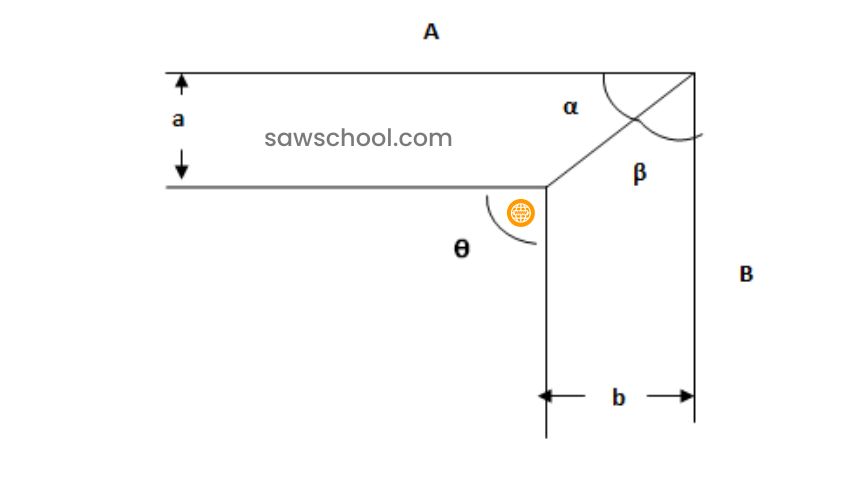

Miter Angle Formula

Professionals use different types of formulas all the time to determine the accurate miter angle. You can also check my article Who Uses A Miter Saw And Why if you are interested. As mentioned above, the basic formula is simple. When two pieces of board are of the same width, you can identify the angle by dividing the entire angle by two.

Consider the whole angle to be theta, the Greek letter (θ). So, if you want to find out the angle for each board (considering that the width of the boards are the same), the formula would be-

Angle for each board = θ / 2.

But what happens when you are joining two boards that are not similar in width? How does the formula change, then? Well, the formula will be different, depending on what angle you intend to join the boards.

For instance, let’s say you are joining two boards, namely A and B, of the same width at a 90-degree angle. The formula would be-

Board ‘A’ miter angle = arctangent (a / b)

Board ‘B’ miter angle = arctangent (b / a)

Here, ‘a’ refers to the width of board A and ‘b’ refers to the width of board B.

The formula becomes more complicated when you want to join the boards at a different angle than 90 degrees. Let’s take a look at the formula suitable for such a situation. Consider A to be the narrower board which has a width of a, and B to be the broader board with a width of b. The formula would be-

Board A miter angle = arctangent (n x sin θ / (a + b x cos θ))

Board B miter angle = θ – Board A miter angle

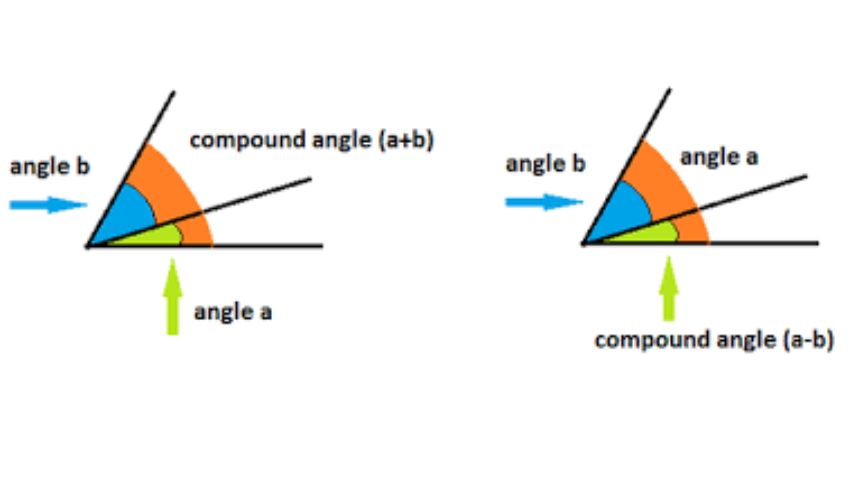

What Is A Compound Angle?

The compound cut consists of a bevel and miter angle. It’s particularly applicable when you are using a compound miter saw. It’s comparatively complex to calculate because there are multiple aspects to consider.

Compound angle comes in handy when you are making posts and boards, n-sided boxes, n-sided pyramids, etc. As complicated as the calculation is, it needs to be precise.

Why Use A Calculator For Miter Saw Cuts?

You must be wondering why professionals use a calculator when operating a miter saw. The answer is simpler than you think. Even though using a miter saw is easy and convenient, the final result comes down to accuracy.

There are numerous measurements and calculations involved in preparing a perfect piece of material. Using manual calculations will not cut it for professionals because a small deviation can ruin the entire project.

So, whether you’re measuring the whole length of the thing you are building, calculating corners for a frame, or cutting repeatable pieces, the measurement has to be precise. It’s better to do the calculation before getting started with your project. This way, you can save time and get perfectly cut materials.

Another benefit of using a calculator is to reduce the time required for measurements. When you are manually creating and executing the formula, it takes a long time to get the results. In a professional setting, there are thousands of materials waiting to be cut. They all require a different formula to find at what angle to cut them.

Calculating the angles and then measuring them require a long time. That’s where a calculator comes in handy. With an accurate calculator, the calculations will become a lot easier and more prompter than before. All you have to do is to input the numbers in the formula, and you will get your answer.

That’s why investing in a high-quality calculator is never a bad idea, especially if you are prepared for a larger load of work coming up. As small as the tool is, it can make your workstation a lot more versatile than before. So, don’t forget to add this to your list when creating a workshop that has a miter saw.

Final Words

When you are dealing with complicated measurements and calculations, it’s better to be certain. A minor deviation in calculation can become a major inconvenience when you are joining the pieces you cut. So, always keep a calculator near at hand for all your calculations.

It not only makes your job easier but also saves you time. You can simply put the formula in the calculator and get the results without breaking a sweat. Manual calculations can never be a solution to professional miter saw cuts.

In addition to using a calculator, make sure that the miter saw is set to the right angle and is cutting the pieces with precision. Everything should be to the point for the final outcome to be accurate.