Everyone knows that you can’t bring a sword to a gunfight. Similarly, you can’t bring a handsaw in to do a chainsaw’s work. Different types of saw blades have different functionalities and it’s all due to the types of variable blades they sport.

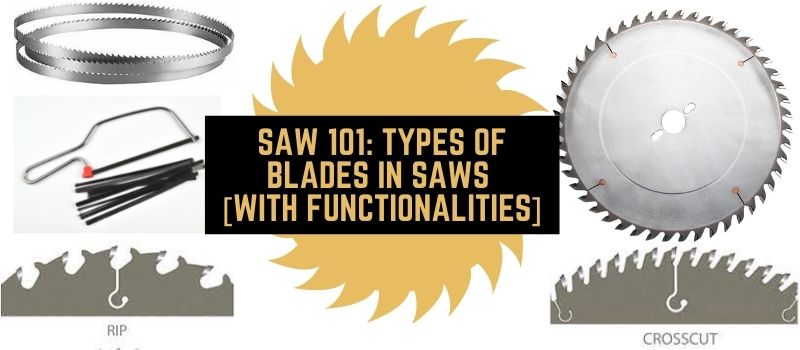

Some common saw blade types are – jigsaw, rip cut, cross cut, circular, chain, handsaw, reciprocating, stone cut, veneer, steel cut, segmented, double-ended blades, etc.

Generally, the flat blades are used per the traditional push and pull method for linear cuts across the wood panels. And circular blades, segmented blades, etc. take care of the angular separation.

I plan to talk about a few of these blades today to inform you of the purposes they serve. So, stick around to find out what sets a certain saw apart from the rest.

Types Of Saw Blades & Their Purposes

Cutting through wood, metal, or similar hard surfaces – saws were pretty much invented for this one specific purpose. However, with time, we’ve reinforced many other blade styles to adapt to variable work methods. Such as –

Hand Saw Blade

Hand saw blades are the most ancient forms of saw blades. Composed of just a sharp stone or piece of metal, our ancestors used to use the pointed end to cut meat, bones, etc. With time, they learned to weld the blade with fire to strengthen the blades even further for advanced woodwork.

But nowadays, by hand saw blades, we refer to manual saws with serrated metal blades. It can be one wide blade for consistent woodworking, or a hack-saw-like pointed blade for additional sharpness while cutting.

Functionalities

- Reliable day-to-day woodcutting saw

- Great for cutting semi-sturdy surfaces

Plytooth Blade

Plytooth blades are a variety of circular saws. But normal circular saws produce a lot of splinters since the shredded wood goes flying after the saw powers through it.

The plytooth blades have numerous small teeth-like segregated edges to cut with more finesse.

Functionalities

- Minimizing the number of splinters while woodcutting

- Specialized for plywood sheathing

Rip Cut & Cross Cut Blades

Rip cut blades cut parallel to the wood grain. Alternatively, cross-cut blades cut perpendicularly & utilize the pull stroke.

Functionalities

- Rip cut blades are primarily used for thinning the wood

- Cross cut blades cut perpendicularly to shorten the wood

Band Saw Blade

Many confuse the band saw blades with the hand saw ones. In reality, it’s an amalgamation of hand saw blades and circular saw blades. It’s a power saw that involves a long sharp blade with a circular tip at the end.

Functionalities

- Used for both woodworking and metalworking

- Used to cut surfaces in both curves and straight lines

Zinc Blades

Zinc blades often have an iron base with galvanized zinc on top for sturdiness. They’re typically not used for woodcutting.

Functionalities

- Cutting large blocks of salt

- Strictly for kitchen uses

Removable Blades

The removable blades fall under the combined or specialized saws category. The saws come with a strengthened handle with detachable blades and include variable blade varieties. For instance – you can simply detach a blade with a rip saw cut, and install one with a jig saw cut instead.

Some of these saws include scopes for power blades as well. The handle is equipped with a motor and you can easily switch from circular blades to double joint blades and more.

Functionalities

- One saw serves many purposes at once

- Saves both time and energy

- Can replace broken blades with sharper ones easily

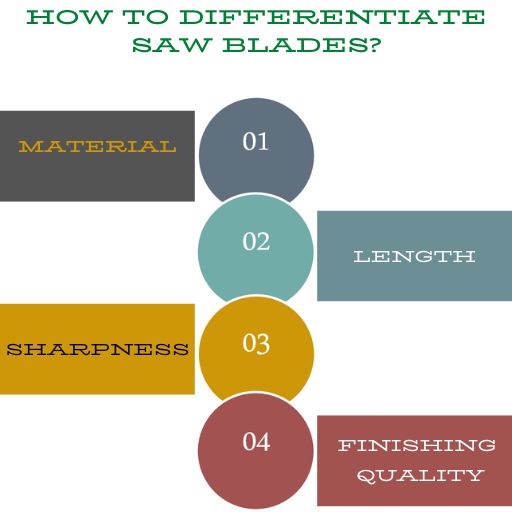

How To Differentiate Different Types Of Saw Blades?

Rip-cut saws can’t cut curvy lines, unlike circular saws. Again, zinc blades can’t cut wood, unlike Miter saws. Why?

Here’s how you can differentiate the types of saw blades –

Material

Nowadays, steel or reforged steel blades are most used for both hand and power saws. Again, carbide blades are crafted as well for further efficiency and sharpness.

Alongside these two, brass, iron, zinc, copper, etc. is used as well for strengthening purposes. Iron blades are galvanized by steel or zinc to make the blades fiercer.

Again, you can find serrated diamond blades as well, which can cut through extra solid surfaces like concrete, asphalt, and even large blocks of the diamond itself.

Length

Longer blades cover more distance over time compared to shorter blades. When the blade is long, it can take out more material at once.

On the other hand, with short blades, it’s easier to achieve finesse in terms of craftsmanship. It’ll take comparatively longer to cut the same amount of wood. But you’ll have a smooth finish quality with finer details.

Sharpness

If the blade is pointy like hack saws or jab saws, then the pointed sharpness will come in handy to cut big wood panels. Again, slightly dull but wider blades like heavy rip-cut saws are better for cutting thick wood or multiple panels at once.

Finishing Quality

Broadly, there are two types of finish quality after cutting. The wood, drywall, etc. will either have a rough or a smooth enough finish depending on the cutting blade and method.

Blades with distant teeth and wide surfaces are better for rough finishes. The TPI or Teeth Per Inch magnitude for these large blades is usually around 1 to 7-8.

Due to the low amount of teeth per inch, these saws are better for cutting down humongous logs into smaller pieces. However, they can’t provide an equally smooth transition.

For smoothness, the TPI of saw blades should be at least 10-11, if not more. Usually, compared to low TPI saws, high TPI saws are more petite. So, it’s more convenient to move around the corners for a smooth finish.

Final Word

My goal today was to educate you guys on some of the most common types of saw blades and their functionalities. Systematic and sustainable woodworking procedure requires a vast knowledge of these blades.

Because using the wrong blades will ruin the quality & sharpness of the saw with time.

So, make sure to research properly before doing some DIY around the house. Plus, use proper gloves and helmets as well before using power saws to prevent unfortunate accidents.

References:

1. Wikipedia