Even in prehistoric times, human beings realized the importance of creating different products for different purposes.

Saws weren’t any different.

If you go through the archeological records, you’ll find that they had specialized saw-like instruments just for cutting animal bones and meat, and again, saws with larger blades for cutting down tree logs.

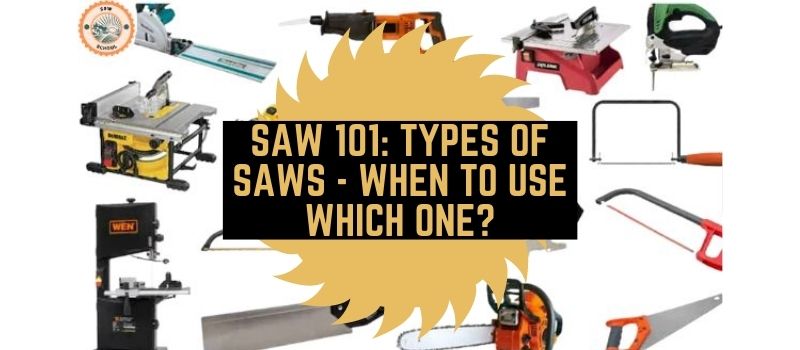

Nowadays, you can find hundreds of different types of saws for woodcutting, metal cutting, bonsai pruning, hacking, etc.

Some of the most common types are – hand saws, rip cut saws, fret saws, bone saws, Miter saws, chainsaws, Table saws etc.

Today I’ll provide an overview of the basic kinds of saws based on different criteria. So, tune in to find out if you’ve been using the wrong saws for the wrong work all your life.

Types Of Saws [Criteria: Material]

Did you know only diamond blade saws can be used to cut chunkier diamonds and give ’em manageable shapes? Similarly, wood, metal, titanium, obsidian, etc. kinds of materials require specific types of saws. Here’s an overview of a few saws depending on the operable material –

Pull Saws

The traditional saws use the push and pull principle for cutting wood primarily. A pull saw focuses on the pull stroke to cut down wood faster. These saws usually have long handles to give sawists more surface for balanced strokes.

Pruning Saws

Pruning saws are quite compact and lightweight compared to other types of saws. You can use them just like normal scissors. These saws help to prune the bushes, bonsais, etc., and prevent unwanted growth.

Hack Saws

Hack saws are used to cut metal pipelines, window bars, etc. They work just like rip saws, but the blade consists of strengthened material like reforged steel, aluminum, etc.

Types Of Saws [Criteria: Purpose]

A banker’s skill set is completely different from that of a pilot. Similarly, not all saws can take care of all sorts of tasks. Take a look at the following purpose-specific saws –

Jab Saws

Just like you can jab an opponent with the sharp end of a sword in a dual, jab saws can jab softwood, metal, etc.

These saws have super sharp, steady, and pointy ends which can break through a few layers at once. You can then use that entry point to cut down the wood panels or walls directly.

Circular Saws

Circular saws are practically rounded chainsaws. Instead of the chain system, the blade itself rotates to facilitate the spinning action that converts into additional sawing force.

It’s difficult to control the circular saws manually due to the fast spinning action. Without proper precautions, you can even lose a finger or two.

Types Of Saws [Criteria: Power]

Cutting wood or metal takes a considerable amount of effort. Hence, it’s important to find efficient tools to save both precious energy and time. Here’s an overview of the two most popular power saws nowadays –

Chain Saws

Industrial powerful chainsaws can cut down hefty trees with elongated log diameters in a jiffy. The blade involves a motorized chain system which amplifies the sawing speed and forces almost exponentially.

Table Saws

Table saws, as the name states, remain stationary. In other cases, you push the saw onto the wood. But with table saws, you push the wood onto the table saw instead.

You can create both straight and curved cuts depending on how smoothly you can change the positioning of the wood.

Types Of Saws [Criteria: Intricacy]

To ensure intricacy i.e. to maintain the littlest details in the woodworking projects – carpenters typically use combined saws the most. Because with combined saws, it’s easier to control the mechanism of the blade, especially if you want to finish faster too.

Intricacy requires time and patience, just as much as skill and enthusiasm. Here’s a rundown of the different types of combined saws that you can use to curate exquisite designs –

Jig Saws

Although Jigsaws often have motors, they’re not as powerful as industrial-level power saws. You can use these saws to get near-perfect round or curved cuts on wood surfaces.

Miter Saws

Like Jigsaws, you can use Miter saws to get angled and rounded cuts instead of strictly horizontal or vertical ones. Circular saws like Miter saws are super helpful to craft design-specific wooden furnishings.

Which Kind Of Saws Should You Store In Tool Sheds?

Although there are numerous types of saws, you don’t have to have all of them to fulfill your day-to-day needs. The following three types of hand-held saws will take care of most of the woodworking projects around the house.

Rip Saws

Rip saws have always been a must-have tool in mechanical sheds even in our great great grandfather’s times. They’re the advanced and consecutively, technologically accurate form of the ancient hand saws with wooden handles.

With rip saws, you simply push and pull the blade by grabbing the handle firmly until you get the desired cut. Admittedly, it takes a lot more muscle power, but in terms of hand-held efficiency, rip saws are undoubtedly the best.

Cross-Cut Saws

Cross-cut saws have long and substantially narrow blades with strengthened wooden handles. They are used to convert spacious panels into workable pieces to make the woodworking process easier.

Bow Saws

If you’ve got a habit of cutting down tree branches for firewood, bow saws will come in super handy. These saws are universally used to cut semi-sturdy wooden panels. You can also use bow saws to get artistic enough curves in a panel if you don’t have Miter saws lying around.

The Bottom Line

There are innumerable types of saws to handle both day-to-day operations and industrial-level mechanisms. Carpenters mostly use power saws to cut down huge tree logs and double-cut saws to carve intricate wood designs.

Other than these, there are some unique saws such as biscuit joiners, which can cut wood blocks into perpendicular segments and glue the endings subsequently. Again, you can find musical saws which, surprisingly enough, work just like a normal violin or cello.

References:

1. Wikipedia