Before purchasing a saw, there are three things you should consider – material, sharpness, and functionality. Here, the last factor i.e. functionality is heavily dependent on cut types.

Rip cuts, cross cuts, bevel cuts, and miter cuts are the most prominent woodworking cuts in saws. Other than these, dado cuts, floorboard cuts, farmer’s cuts, ice cuts, compass cuts, panel cuts, and even musical cuts are available for saws.

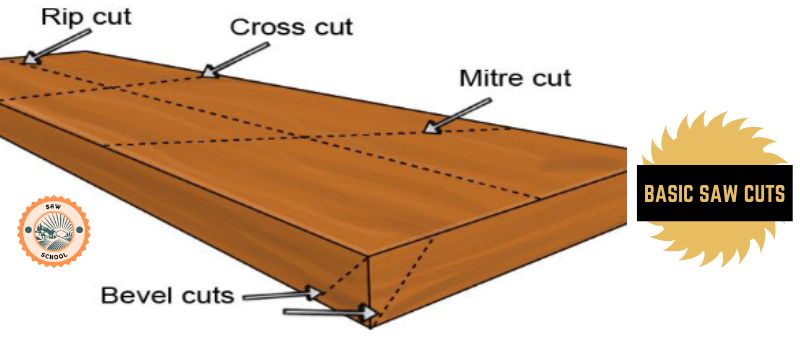

Basic Saw Cuts

Based on the traditional push and pull method, here are the four most common saw cuts you’ll find nearby –

Rip Cut

A rip cut is the ultimate push stroke cut. In rip-cut saws, you’ll use heavily sturdy blades with low TPI. The cut helps to tear down large logs, floorboards, walls, etc. aggressively.

Cross Cut

As opposed to rip cuts, cross cuts cut perpendicularly while rip cuts cut parallelly compared to the stationary wood grain. Most table saws utilize cross cuts for precise cutting.

Bevel Cut

Bevel cuts or beveled cuts cut towards neither the parallel nor the perpendicular direction. Instead, you’ll place the blade at a 45° angle to enhance efficiency. The shift in angle in the table saws gives better control to the carpenters.

Miter Cut

Lastly, the miter cut requires a miter gauge for calculated cuts with the least amount of fallacies. While it’s best to use Miter saws for miter cuts, you can adapt your table saws too by adjoining a miter gauge for proper measurement.

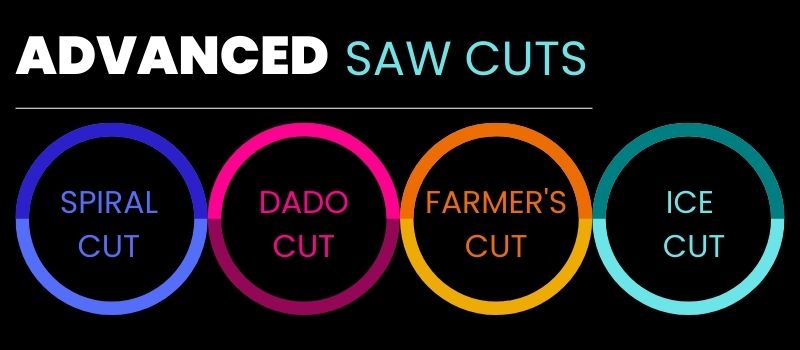

Advanced Saw Cuts

Time to look into some unconventional saw cut methods!

Spiral Cut

Mostly rotary saws utilize the spiral cut. Its functionality is to make precise cuts into floorboards, walls, etc. The surface should be thin enough for the blade to penetrate through the panels easily.

Dado Cut

Dado cuts are a must for woodworking projects. You’ll need specialized dado blades to make dado cuts. You’ll get a sleek one-directional cutting spread with the usual blades. However, with Dado cuts, you’ll get to snip off a wide rectangular portion of the wood to create adjoints.

Farmer’s Cut

This cut requires a coarse blade with unwittingly strong teeth. Typically used for outdoor purposes such as – cutting down thorny bushes in the middle of the field with one fine chop.

Ice Cut

Ice cut is reserved for ice saws, and isn’t used for woodworking projects. The cut requires large saws with non-skid blades with distinguishable coarse teeth. And, yep. You’ll need ice-cut saws to chop down large blocks of ice from the source mountain or lakes.

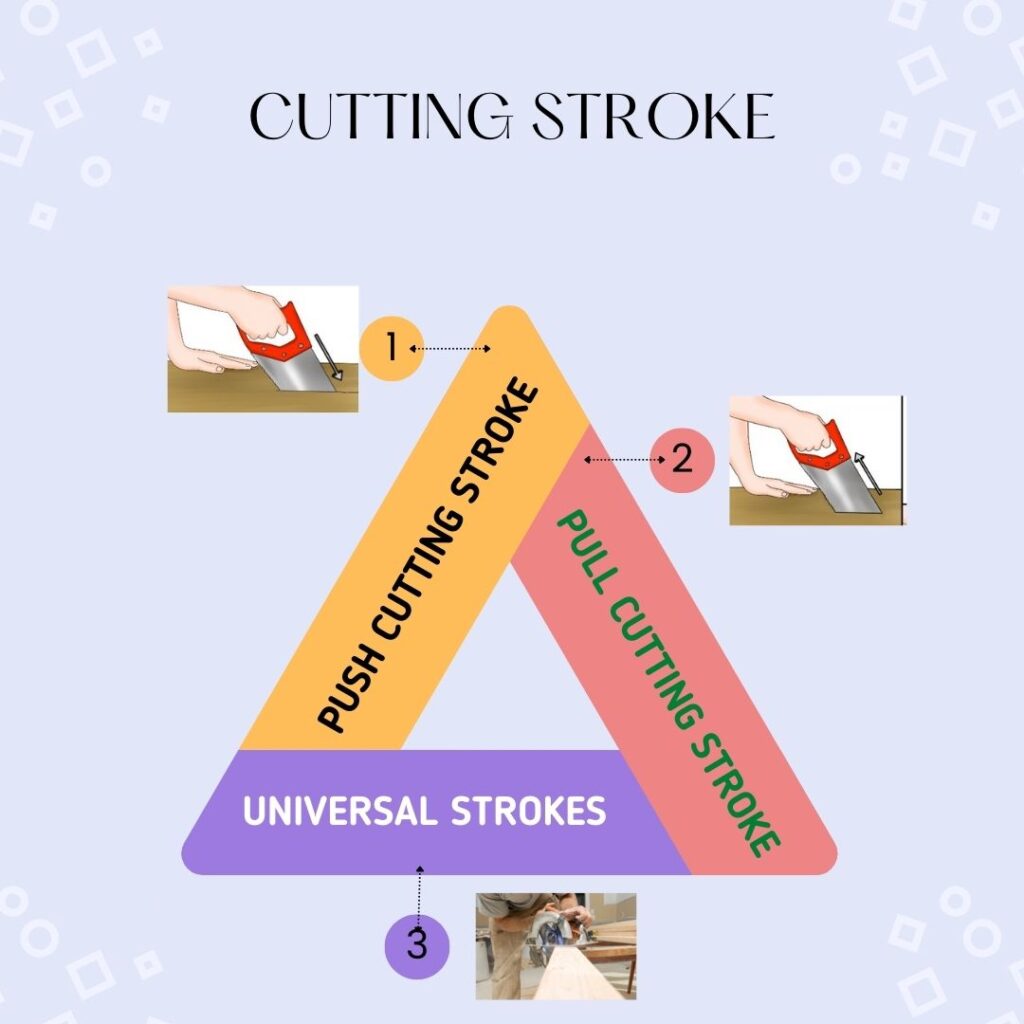

Cutting Stroke – How Does It Influence Cut Types?

Simply put, the cutting stroke refers to the mechanical motion of the various types of cuts on respective surfaces.

The cutting stroke of saws is rooted in the prehistoric push and pull method. Just like the tide and ebb of rivers, oceans, etc. result in the formation of small islands, the push and pull of the saws create new shapes and designs within the wood.

Check out how the different stroke forms influenced and complemented the contemporary saw cut types –

Push Cutting Stroke

In this form, the saw is usually aimed toward one’s own body and the saw only experiences push strokes. The carpenter keeps the panels steady in front of him and runs the saw towards himself to cut the wood.

Push strokes are famous for chopping down large chunks of wood, floorboard, soft metal, etc. It’s also the most natural and primal stroke for handsaw users.

The saw blades are wider for push strokes to efficiently smash through large pieces of wood. The TPI magnitude is low as well. The blade is made of coarse and long-lasting material to endure the constant friction between the panels.

In addition to low TPI, all teeth point away from the direction of the handle. Hence you get the maximum force while pushing the saw down on the wood at minimum expense.

Rip cut saws are well-known for the push cutting stroke. Furthermore, Miter & floorboard saws also utilize this specific stroke for enhanced functionality during cutting.

Pull Cutting Stroke

Chopping down wood using the pull stroke wasn’t as famous when saws and similar equipment were first invented.

In fact, it didn’t become as well known until the very end of the 20th century. People finally started to focus on the intricate aspects of woodworking during this time, instead of just roughly chopping everything up with no mercy.

The pull stroke requires finer blades and the finest carpenters who can control the blades like the back of their hands. Expectedly, the TPI magnitude is considerably high as well compared to push-cutting stroke saws.

The teeth will somewhat point towards the handle, to aid the cutting strokes while pulling the saw. The carpenter gets a significant amount of control over strokes due to this feature.

Universal Strokes

Even a few hundred years ago, you couldn’t use the push stroke on a saw specifically manufactured for pull strokes. For instance – for push stroke saw cuts, the teeth were further apart and they were positioned abrasively.

Manufacturers did this to prevent teeth breakage while chopping down large wood panels. On the other hand, pull stroke cut saws were much thinner with high TPI. Hence, attempting push strokes would get the blade pretty bruised.

Nowadays, you can find even the most basic saws with universal stroke capabilities. A hack saw is a prime example. With a hacksaw, you can simultaneously use both push and pull strokes to cut wood without breaking the blade.

And when the same blade can endure both push and pull strokes, it’s said to have a universal stroke saw cut. Economically and ergonomically, these saw cuts are much better, since they can serve multiple purposes at once.

Final Word

That’s all I could cover in today’s saw lesson on cut types! Although many of these cuts may seem similar, a seasoned carpenter knows how easy work becomes with the right cut. So, educate yourselves on these cuts one by one and make sure to use proper precautions while investigating the blades.

References:

1. Wikipedia