Whether you’re buying a table saw or already have one, the capacity of the tool often crosses the mind. One part of this curiosity is, can a table saw rip a 2X4? If so, what is the right way to do it?

A table saw can efficiently rip a 2X4 as long as you know what you’re doing. The process can be a bit tricky. However, if you have the right tools and you know the correct method, you can rip a 2X4 in no time.

Let’s not waste any time and get to the process right away.

Can A Table Saw Rip A 2X4?

As I have mentioned, you can easily rip 2X4 pieces with a table saw. In fact, a table saw is a popular tool for this particular task. So, if you have a table saw in your home, there is no need to worry about these wood pieces.

Sometimes, users consider various perks when investing in a table saw. For instance, if you need a table saw for a specific reason, you’ll naturally wonder what other tasks can be accomplished using the same tool.

After all, no one invests in an expensive tool for doing one particular task. It’s normal to have high expectations from a tool that’s taking a fair amount of money from you. That’s why you should always take your time and consider all your necessities before purchasing it.

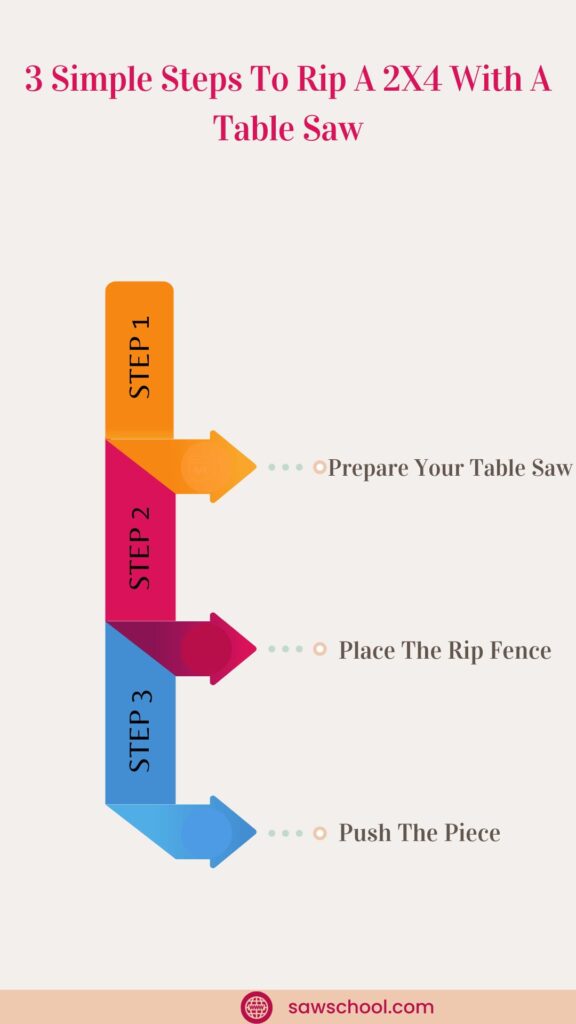

How To Rip A 2X4 With A Table Saw [Step-by-Step]

So, it’s possible to rip a 2X4 with a table saw. But how? I’ve included a step-by-step procedure for you. Make sure not to skip any part of the process below.

Prepare Your Table Saw

The most important part of your process is to set the table saw. If you’re not being careful with it, you will end up damaging a lot of pieces. Not to mention, your safety will be threatened. So, always take your time before cutting.

But the question is, what is meant by preparing the table saw? For starters, you have to unplug the table saw. The table saw should be plugged into the power source only when you’re cutting your material. Other than that, it should always be unplugged, especially when you’re altering the settings.

The next thing to do is to adjust the blade. You have to set it to the highest position. Adjusting the blade can be different depending on the table saw you’re using. Most of the time, it’s adjusted using the arbor nut.

You can also tilt the blade when cutting beveled pieces. Nonetheless, the common type of pieces required is almost always cut at a 90-degree angle. Check if the blade is tilted in the right position.

Sometimes, even when the blade is set to 90-degree, it can be a bit inaccurate. You need to measure the angle with a woodworking square to adjust the blade accordingly. You can also cut a few experimental pieces with the settings before starting your work.

Then, check the riving knife, blade guard, and insert plate placement. They should all be in place to ensure an efficient procedure while keeping you safe. Sometimes, the riving knife may not be aligned with the blade, especially if it’s a new table saw. So, make sure to check that.

The insert plate is another important thing here. It prevents small pieces from falling off.

Place The Rip Fence

Now, you need to set the rip fence according to your required measurement. It’s better to use a measuring tape in this case, even if your table saw has a built-in one. Sometimes the markings can be a bit inaccurate in built-in measuring marks.

Lock the fence in place. Note that the larger part of the woodblock should be on the fence side, and the smaller part should be on the opposite side.

Push The Piece

Place the 2X4 piece in position. When you’re using a table saw, you have to be very careful about pushing the piece. You need to put pressure in three ways. The first thing to keep in mind is to push the piece toward the fence.

You will also have to push the wood block down and forward. Once the wood is inside the blade, use a push block to complete the cut. Table saws can be dangerous tools if not combined with the right accessories.

If you don’t have a push block and you’re looking for options, take a look at the No products found.. It’s one of the most popular push blocks for table saws.

It’s always a good idea to cut a few experimental pieces first. This way, you can see if there’s something wrong with the table saw settings. For instance, the fence might not be in the right position. The insert plate might not be at level with the surface.

Safety Tips

Did you know that thousands of injuries are caused by table saws each year? According to the National Library Of Medicine, the number is over 30,000. In other words, you have to be very careful when operating a table saw. Let’s take a look at some safety tips that you should follow.

- Never ignore your safety gear when operating a table saw. Make sure you’ve protected your eyes, ears, and nose. Table saws can be very loud. You can read the article why is my table saw so loud to get more details.

- The blade should have spikes toward you. In other words, the way you will be inserting your wood piece should be in the direction of the blade spikes. If you don’t do that, the wood piece will bounce and go up in the air.

- Make sure there are no bystanders when you’re using your table saw.

- Always double-check the settings. And while you’re adjusting them, make sure that the table saw is not connected to the power source, even if the switch is off.

- If it’s your first time operating a table saw, locate where the emergency off switch is before getting started. And make sure that you can reach it either by your hand or leg.

- Avoid operating the machine when you’re tired or under medication that can influence your attention. You have to be very awake while using the table saw to avoid accidents.

- Be aware of any loose wires lying around that can make you tip over in the workshop. Keep the area clutter-free.

- Don’t stand directly behind the blade. Instead, stand on the side. This will keep you safe in case there are any kickbacks.

- Make sure every element is in place when you’re using the table saw. That includes the insert plate, the blade guard, the fence, and the riving knife.

- Do not rip materials without using a push block. If you don’t have one, use two push sticks.

Frequently Asked Questions

Can a 10-inch table saw rip a 2×4?

10-inch table saws are most commonly used, while 12-inch table saws are more suitable for industrial use. A 10-inch table saw can perfectly rip a 2X4. In fact, a table saw is one of the most commonly used tools for ripping a 2X4.

What is the best tool for ripping 2×4?

The best tools for ripping a 2X4 are miter saws and table saws. However, you can also use a circular saw if you’re utilizing the tool smartly. You will need clamps when ripping 2X4 using a circular saw.

Final Words

So, the bottom line to can a table saw rip 2X4 is yes, it can. It’s an easy and straightforward process. But the danger of using a power tool remains constant. So, regardless of what tool you’re using, you have to be very careful about safety.

One lousy mistake and you will injure yourself or others beyond imagination. So, make sure to check the user guide and always follow the precautions when operating a table saw.