Miter saws are incredible for day-to-day operations, but they have a few significant fallacies as well. Sometimes, usually after two or three years of use, the miter motors start to spark. Without preventative measures, the situation worsens.

But why is your miter saw sparking?

If your miter saw is sparking, it usually means one of two things. Either the carbon brushes can’t handle the power surge like before, or there’s been a short circuit within the motor.

However, they’re not the only two reasons. Let’s know more about these reasons and figure out their potential solutions.

Types Of Miter Saw Sparking

A miter saw generates sparking due to misplaced friction. Depending on the placement and extensibility, you’ll experience the following types of sparking –

Light Sparking

These are usually not as noticeable. When you’re operating a miter saw to cut pipes, wood panels, firm boards, etc. it’s normal to experience some sort of light sparking.

Generally, it occurs after you turn on the power. The light spark indicates the jump-starting of the motor. Inside the powerful motor, the carbon brush and the armature start to run simultaneously to rotate the blade mechanically.

And when these parts touch and generate heat and friction, you can notice some light sparking around these areas. Although these sparks aren’t necessarily that dangerous, they do play a significant role in wearing out the internal systems.

Heavy Sparking

Light sparking is common, but it can easily become a case of heavy sparking if left untreated for a long time. Over time, the carbon brush wears out due to the constant friction with the armature and other motor parts.

When the wearing out crosses a certain limit, the brush starts to malfunction indicatively. And that’s when you’ll start to see heavy sparks around the miter saw motor area.

The best way to deal with heavy sparking is to keep an eye on the motor after you experience light sparking. Reposition or repair or replace the affected parts in time. Don’t let instances of light sparking go undetected and untreated.

Blade Sparking

Metal blades can spark up a lot and it’s not always a great sign. If the blade is producing light sparks now and then, then it’s quite normal. It’s just the frictional resistance.

However, if they start to spark continuously, then it means you’re trying to cut into a rougher material than you should. Heavy sparks in the blade indicate that they’re overclocking and falling short of cutting into the material smoothly enough.

You should immediately change the blades with prerequisite features in these cases. Otherwise, the sparks will make the teeth dull & can break them, too – rendering the blade useless.

Material Sparking

When you’re using a miter saw to cut copper pipes or similar metallic pipes, you might experience some material sparking. And it’s because you have to use metal or compound metal blades to cut through copper pipes.

Hence, when the metal blade goes on metal pipes, there’s often initial sparking due to heavy friction. The sparking can continue even after the initial penetration. And it can continue through the entirety of the cutting stroke.

The sparking itself is not as dangerous. It’s simply a byproduct of metal friction. But you should still wear safety gloves and goggles to protect yourself while sawing.

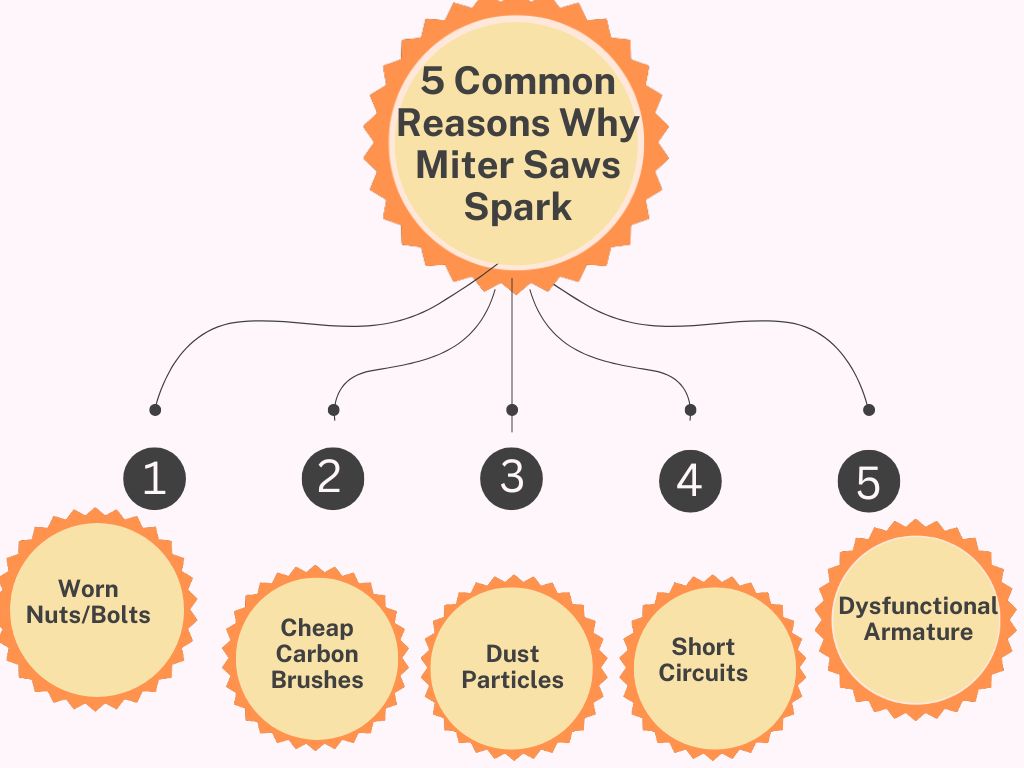

5 Common Reasons Why Miter Saws Spark

When a miter saw is sparking, you should pinpoint the location of the occurrence first and foremost. Let’s have a look into some of the most common reasons why they spark –

1. Worn Nuts/Bolts

If you’re using a cheap quality miter saw with an improper material combination, then the nuts and screws can wear out fairly easily. Sometimes, if water or vapor gets inside the motor, the screws become compromised thanks to rusting.

These compromised nuts and bolts can cause sparking inside the motor. When the saw gets powered up, the abrasion will directly hit the corrosion-affected interface. And the constant friction between the two will generate major sparks.

2. Cheap Carbon Brushes

The carbon brush is the powerhouse of a miter saw motor. It supplies the necessary power to keep the armature going.

Cheap carbon brushes get corroded easily, and sometimes, the upper layer starts to peel off horrendously. The hard carbon in these compromised layers falls off when they’re ferociously in contact with the moving commutator inside the motor.

In the early stages, carbon brushes produce comparatively lighter sparks. As they grow weaker, the sparks start to become far more extensive than before.

3. Dust Particles

If the motor isn’t covered properly, then dust particles can get inside and jam the inner bearings to an extent. When the motor gets the power back, these jammed-up parts can spark up trying to get rid of the particles stuck inside.

This occurs frequently with miter saws since the blade cuts through most materials like butter. Hence, the kerf area gets completely demolished in every possible way. And the material in that area gets chopped into fine dust.

These dust particles later jam up the inner bearings and cause significant corrosion and sparking. To keep this from happening, the motor should stay covered on all sides.

4. Short-Circuits

Power saws have this one disadvantage in common – impromptu short circuits. Inside the miter saw motor, there are different sorts of coils to supply and redirect energy.

If any of these coils overlap due to friction, then it won’t take long for sparks to fly like it’s new year’s eve. Excess friction generates heat, and excess heat destroys the safety layers on top of the charger coils.

After a certain amount of sparks, the coils will cease to work completely. And you won’t have a choice but to replace them before they cause damage to the armature itself.

5. Dysfunctional Armature

The miter blade rotates due to the rotational motion of the armature. It’s the heart of a miter saw.

When you power up the saw, the electrical energy surges through the metallic coils within the armature. The electrical energy gets converted to mechanical energy – which contributes to the actual movement and speed of the blade.

Due to dust particles, faulty carbon brushes, etc., the armature can get dysfunctional. Then you’ll start to see sparks generating inside the armature coils – which isn’t a great sign.

Light sparks inside the armature indicate casual friction between the coils. However, heavy sparks can lead to a drastic increase in temperature – which can cause short-circuits and even potential small fires.

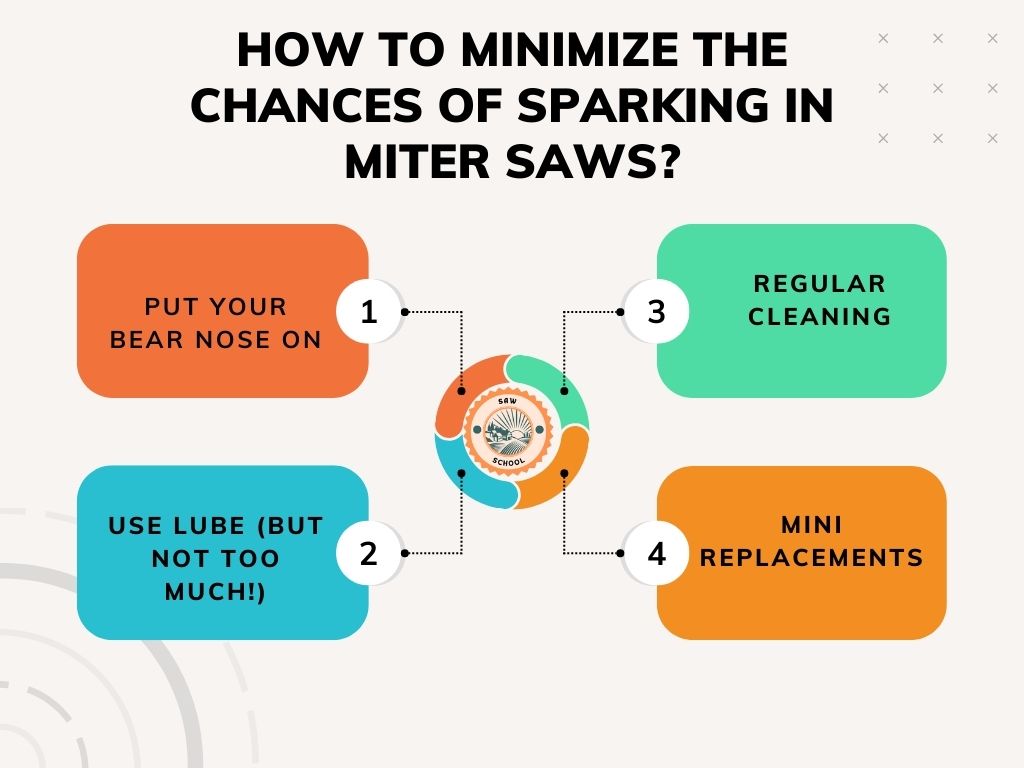

How To Minimize The Chances Of Sparking In Miter Saws?

Like the sparks you feel everywhere when you’re in love, miter saw sparks can and will also generate painful memories of these sparks later in life. You might even need to replace the motor entirely if you fail to fix the issues in time.

Here are a few tried and tested methods to minimize the chances of sparking in miter saws. Detect the causes and employ these ways right after you start seeing light sparks.

Put Your Bear Nose On

Nope, you don’t actually have to get a bear’s nose for this. Simply learn to develop a keen sense of smell to differentiate between different types of sparks in the workplace.

Heavy sparks often create smoke alongside. For instance – if you can smell rustic smoke, it’s probably because of the temperature created from the friction burning the wood.

Again, copper coil sparks and smoke have a different metallic smell to them. You can learn to differentiate between these smells to easily figure out the origin of the sparks.

Use Lube (But Not Too Much!)

Sometimes, it’s recommended to apply some mechanical lube or grease to help the motor function better. Some even apply a little bit of grease along the blade to help it penetrate easily.

If you don’t use the proper amount of grease, then the dry friction can generate unappealing sparks. Again, if you use too much of it, then the surface layers can get too slippery.

The lack of enough friction is also a bad option. Because then there won’t be any conformity within the motor movements.

So, make sure to use just the right amount to keep everything in a pitch-perfect shape. Less lube is better than no lube.

Regular Cleaning

Keep an eye on the condition of the motor and clean it regularly to avoid sparks. If there’s too much grease, wipe it off with a clean microfiber towel before it spreads.

Clean the commutator extra carefully since it’s the part that gets affected by the uninvited grease the most. You can use a toothbrush with soft bristles to clean the precarious areas.

Mini Replacements

Start to repair or replace the damaged bits once you start to see light sparks here and there. For instance – if you see sparks coming from the coils, then it means that the safety covers have been damaged and exposed.

You can repair these coils by adding more rubber insulation. Or you can simply replace them with a new bunch of coils. Decide after scrutinizing the damage on the coils.

Similarly, you can replace/repair the armature coils, covers, carbon brushes, etc., to ensure a safe experience. If you fix the damaged bits in time, the entire motor won’t get compromised.

Wrapping Up

So, why is your miter saw sparking in the first place? Turns out there are multiple reasons – almost all of which involve either the armature or the carbon brush.

Short circuits within the motor can generate sparks too. If left untreated, these sparks can ruin the quality of the motor altogether. Hence, take necessary steps before time runs out, and exercise proper safety measures every step of the way.