Many still bear the misconceptions that saws are for cutting wood only. But that’s not the case at all. Normal saws and some of the power saws, like miter saws, can cut through metal, plastic, etc., pretty easily nowadays.

But can miter saws cut plexiglass? That’s the raging question.

And the answer is yes. Miter saws are actually one of the best power saws for cutting down plexiglass or acrylic sheets. Flexibility and stability – you can avail the best of both worlds while cutting acrylic sheets with miter saws.

But I’m sure you’ve got many more questions related to the topic. Such as – is it safe to use the same blade for wood and glass in miter saws? Or is it okay to cut multiple layers of acrylic sheets in one go?

I’ll try my best to answer all of these most-asked questions in today’s write-up. So, keep reading!

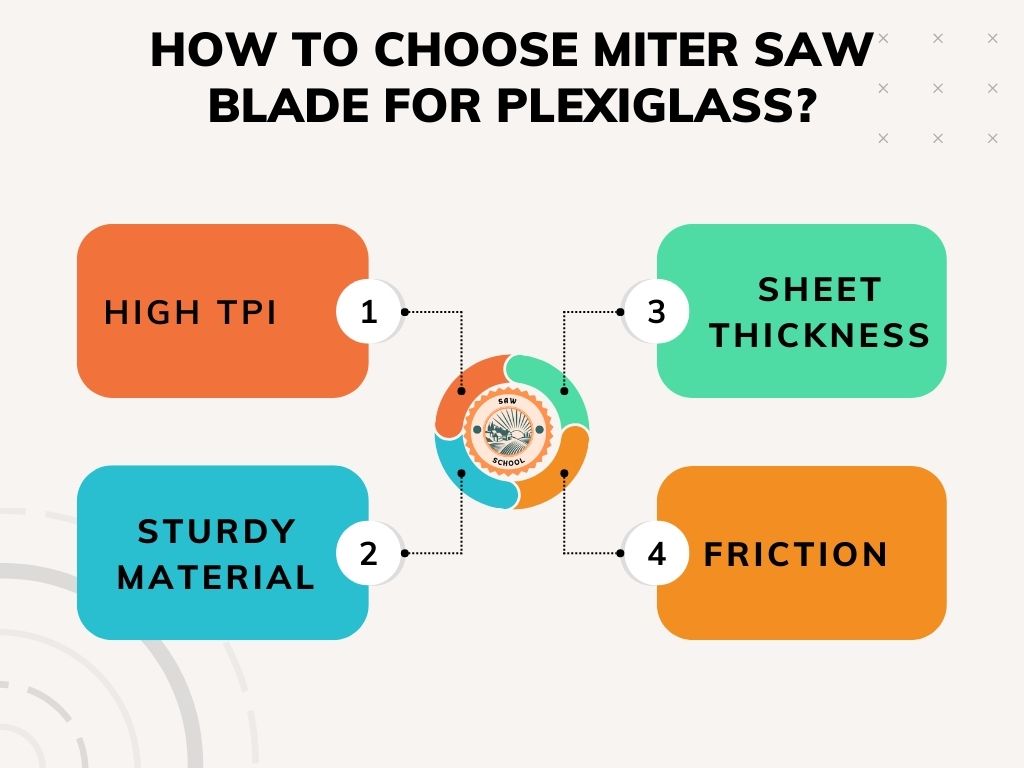

How To Choose The Right Miter Blade For Plexiglass?

Plexiglass isn’t your run-of-the-mill reflective glass. It’s primarily plastic, used as a replica of glass.

While plexiglass harbors many of the same properties as regular glasses, they do require special care and maintenance. And that applies to the selection of miter blades as well.

Here are some factors you should consider before choosing the right miter blade for cutting plexiglass.

High TPI

You can’t afford to have thick and unprofessional chips and cracks in the middle of an acrylic sheet. Plexiglass is valued for its fine-looking nature, and you can’t disrupt that.

And it’s easier to mess things up with acrylic sheets since they are completely transparent. With the wrong blade, you’ll visibly get to see how badly you cut through the sheets. Fogginess is a side effect here, which is hard to get rid of.

To prevent all of these, you’ll need to make sure your blade is capable of fine cutting. And that’s why the TPI is important.

With saws, the TPI counts equate to precision. Saws with comparatively fewer teeth per inch rip the boards apart. Proactively, saws with a high TPI count cut through the boards as if they were melting butter with a hot knife.

And that’s exactly the kind of saw blades that you should use to cut plexiglass. If you want my personal opinion – I’d suggest going for as many teeth as possible.

Take the No products found., for instance. It’s my go-to blade for cutting through soft plastic with the in-house miter saw.

I have this blade in two sizes. The first one has a diameter of 7-¼” with 128 teeth. And the other one is slightly larger, with a diameter of 10″ and a whopping 200 teeth.

The combined aluminum blade, in combination with this many sturdy teeth per inch – gives the cleanest cut. Not just plexiglass, I’d recommend this novelty blade for cutting PVC pipes with a miter saw too.

Sturdy Material

Here’s what you don’t want to deal with miter blades – shakiness, i.e. lack of stability. The blade should be able to hold its own while it’s cutting through soft plastic or vinyl.

A combination of industry-grade aluminum, plastic, and reforged steel works really well for acrylic sheets. Furthermore, the material should also have the following characteristics – corrosion resistance, abrasion resistance, etc.

Oh, and get carbide-tipped teeth, please. It’ll provide you with the extra boost you need to penetrate through the sturdy sheets.

Sheet Thickness

You should select circular blades for your miter power saws based on the size and thickness of the acrylic sheets. Because it’s generally not a great idea to try to cut through thicker panels with a sleek blade.

The blade itself could break, or at least get bent in such cases. So, choose the blade wisely in advance. The blade I recommended above can easily handle up to ⅛” thickness. Hence, you shouldn’t be using it for sheets thicker than that.

There are many other dedicated blade options in the market for thicker and larger acrylic sheets, such as the No products found., the sister blade to the No products found. Swift Cut.

It’s an industrial-duty blade equipped to handle the roughest surfaces and can penetrate thicker than ⅛” if needed. So, don’t forget to switch to an alternative like this one if you happen to work with thicker acrylic sheets.

Friction

Friction isn’t good news for plexiglass. Too much friction can not only cause little chips and cracks, but it can also increase the overall temperature around the cross-sectional area.

And I don’t have to mention why high temperatures and plastic don’t marry well with each other. If the miter blade causes too much friction, you’ll risk melting the sheets too.

High TPI blades have a nasty habit of creating lots of friction during the sawing procedure. So, while purchasing miter blades for cutting plexiglass, check for frictional resistance. If the blade sparks or keeps on sparking on normal surfaces, then you shouldn’t get it for acrylic sheets.

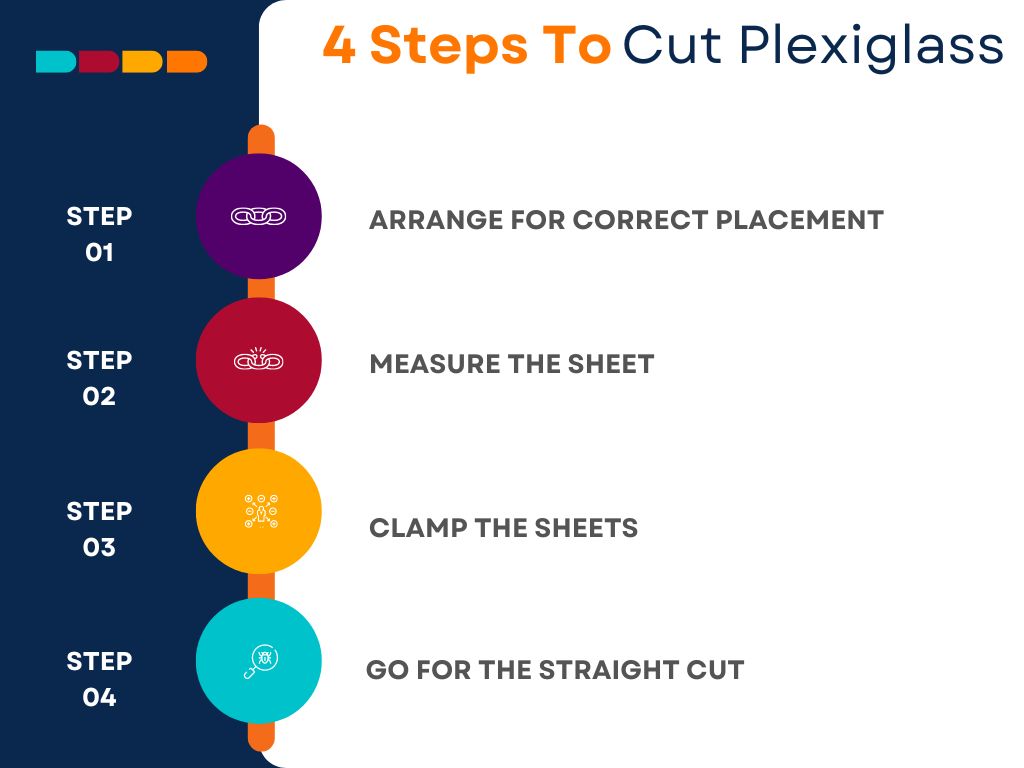

How To Cut Plexiglass With Miter Saws?

Plexiglass is far sturdier than normal glass. But that doesn’t mean you won’t need to follow proper guidelines while cutting through such surfaces.

Here’s how you can use a miter saw to cut plexiglass with the least amount of casualties –

Step 1: Arrange For Correct Placement

Placement is of utmost importance to reduce the chances of potential casualties during the sawing procedure. Check and then recheck the positioning of the instrument and the sheets.

If you’ve not changed the circular blade already, then do it. While you’re changing the blade, make sure that the workbench is empty, and wear safety gloves for sharpness. Check the following guide if you need further instructions.

After securing the blade, miter gauge, and beveled gauge, place a foam bed or thick wood panel on the fence. It’s not recommended to keep acrylic sheets directly on the fence to avoid friction, discoloration, and potential smudging.

Step 2: Measure The Sheet

Measure the length and thickness of the plexiglass. Recheck if you’ve selected the right blade according to its thickness.

The kerf measurement doesn’t matter that much with plexiglass due to the sleekness of the blade. So, you don’t have to worry too much about the discrepancies in this case.

Simply take linear measurements and mark the lines according to your needs. It’s best to cut from a specific side. That way, you’ll get more control during the procedure.

With manual tools like sharp knives, scoring is needed before cutting semi-malleable surfaces like plexiglass. Scoring refers to the process of scratching repeatedly to create a linear groove deep enough to penetrate the plexiglass surface.

But that’s not needed with a powerful miter saw. You can directly penetrate the glass with a power saw. So, refrain from attempting to score the glass if you’re using a miter saw. You can use colorful masking tapes to indicate the marking lines if you don’t want to use direct markers on the glass.

Step 3: Clamp The Sheets

Use a clamp to keep the sheet and the wood in place over the fence. You can get elongated clamps to cater to widespread acrylic sheets for miter saws.

Make sure that the clamps don’t put too much pressure on the acrylic sheets. Despite being plastic, they’re considerably fragile compared to wood or metal. Hence, the pressure might cause them to break if it’s too high.

Step 4: Go For The Straight Cut

Lastly, cut through the sheet like you’d cut any other material. It’s just like cutting copper pipes with a miter saw or cutting ABS pipes with a miter saw.

Fix the miter gauge for the last time to make sure the blade cuts perpendicularly on point. Align the fence with the wooden board/foam bed with the miter gauge & the blade. After checking and adjusting everything, take control of the handle and cut through the plexiglass like an absolute pro.

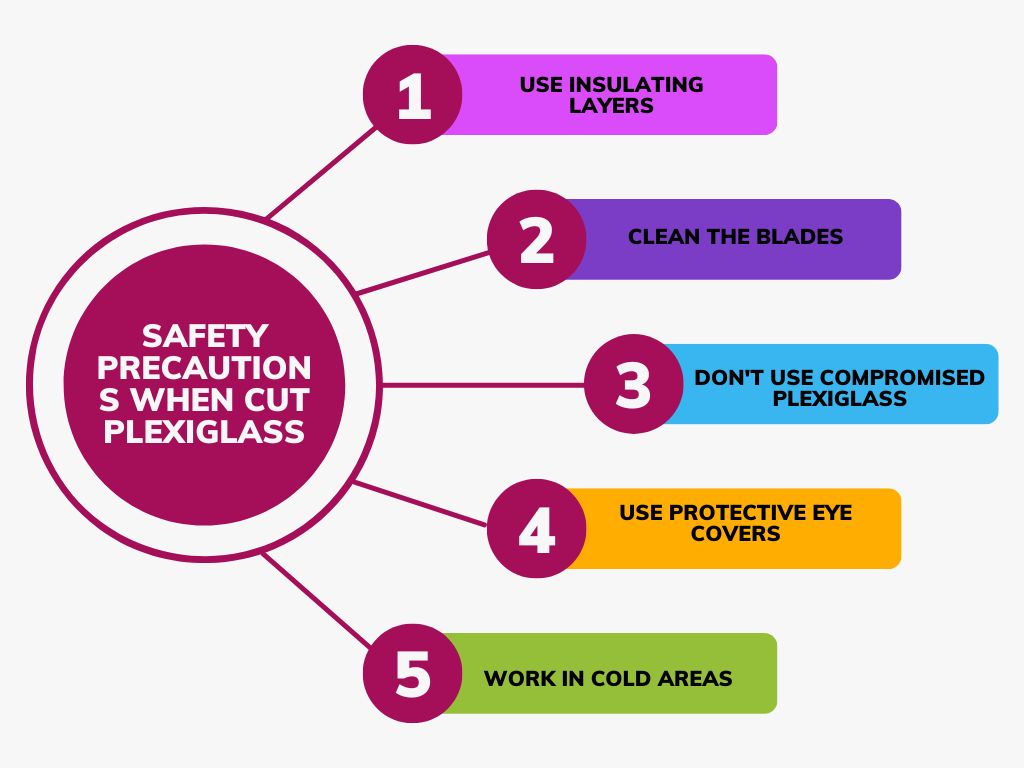

Cutting Plexiglass With Miter Saws: Safety Precautions

You’ll need to exercise extra precautions while cutting plexiglass with a miter saw. The glass interface gets shattered to the point of being dust-like particles. And the acrylic plastic dust can cause lifelong respiratory tract issues later on

So, adopt the following measures if you’re dealing with acrylic sheets in the workshop –

Use Insulating Layers

You should use insulating layers like foam covers or old/thick wooden boards for two primary reasons.

Firstly, the layer helps to cover up the screeching sound of the miter blade sawing through the sheets. And secondly, they help to reduce the vibrations during the procedure.

Less vibration means cleaner cuts. If you place the sheets directly on the fence, they’ll vibrate too much. The constant vibration can cause the plexiglass to break as well. To keep that from happening, use a soft board to cushion the pressure.

Clean The Blades

Before cutting plexiglass with a miter saw, always dust and clean the circular blades. It’s super important to remove the residual plastic from the previous round.

Since the TPI is quite high, the teeth stay very close to each other in these blades. So, residual acrylic plastic particles can get inside the gap within the teeth and jam them to an extent. And when that happens, you won’t get a clean cut.

Cleaning the blades will rejuvenate the strength of the teeth, and you’ll achieve firm and crystal clear strokes afterwards.

Don’t Use Compromised Plexiglass

If the plexiglass has already been tampered with, it’s best not to place it under the blade of a miter saw. When the saw cuts through the surface, the interface will vibrate accordingly.

So, if the plexiglass is already brittle, the added vibration will simply push it over the edge. And I surely don’t have to tell you about the hazardous side effects of shattered glass sheets.

Use Protective Eye Covers

Plexiglass is not as sharp as real glass, but it still packs quite the punch. Use protective eye and ear covers to keep the plastic particles from hitting your face while sawing.

And it’s equally important to refrain from accidentally inhaling the plastic dust. Wear proper work helmets or masks to completely cover your nose and mouth while working.

Work In Cold Areas

Plexiglass melts easily. So, keep your workstation in such a place where there’s no direct heat or fire.

Because keep in mind that the blade will cause some extra friction which will increase the temperature momentarily. That’s why you should maintain a low temperature in general.

Final Word

So, can miter saws cut plexiglass or not? Some recommend going for it, again some also end up advising against it. Neither of them is wrong from their perspectives actually.

Miter saws are great for cutting fully uncompromised plexiglass/acrylic sheets. But they aren’t as great for cutting somewhat broken acrylic panels.

Keep away from cutting fragile plexiglass with miter saws. You’ll risk breaking and ruining the panels entirely with all the vibrations from the powerful sawing. Only cut fully intact plexiglass with no visible chips or dents. And always wear hand gloves to keep your fingers secure.